Holly Kaplansky

May 23, 2019

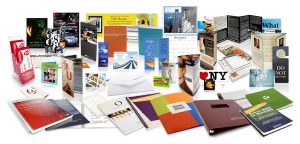

There are cost savings to be had at every step of the printing process from design to finishing. Consider these cost-savings ideas when you are planning your next printed material.

- Use standard paper sizes. Unusual or non-standard paper sizes require extra time in cutting and finishing.

- Design for standard paper sizes and create layouts that don’t require cutting to a finished size or shape.

- Use paper that the printer has on hand rather than ordering special stock. Special order papers not only increase the cost, but the time to complete the job will increase as well.

- Avoid bleeds, i.e. having the image run off the edge of the paper. Bleeds require the edges of the paper to be trimmed. This can cost you more in paper and time.

- Have multiple pieces printed at the same time. If you need business cards for several of your employees around the same time, have them printed all at once. Ganging up printing jobs saves set-up time and therefore cost.

- Print more now rather than reorder later. In most cases, it is considerably less costly to print a larger quantity now than submitting another order at a later date.

- Turn a newsletter or brochure into a self-mailer. You’ll save the cost of an envelope and possibly postage costs as well.

- If you do want to use an envelope, design the piece to fit in a standard envelope.Custom-sized envelopes add to the cost and the complexity of the job.

- Reduce the weight of the paper. Heavier stock means higher paper and mailing costs.

- Have your printer design the project. It will save you time, and the files will be print-ready with no problem. Everything will be set up properly to print right from the start.

- ASK YOUR PRINTER how to save money! You’ll be surprised by what they may say.

Submitted by Holly Kaplansky, owner of Minuteman Press Newark